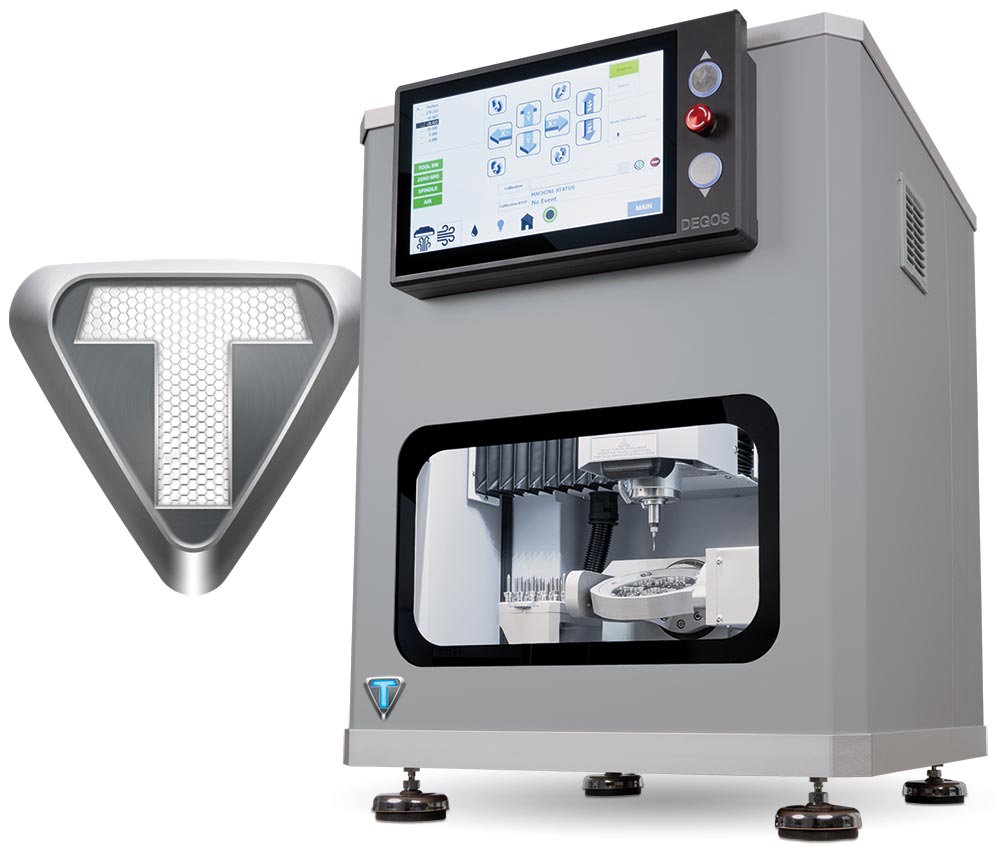

DEGOS Titanium D3

The compact all-rounder.

Enormous power, compact dimensions.

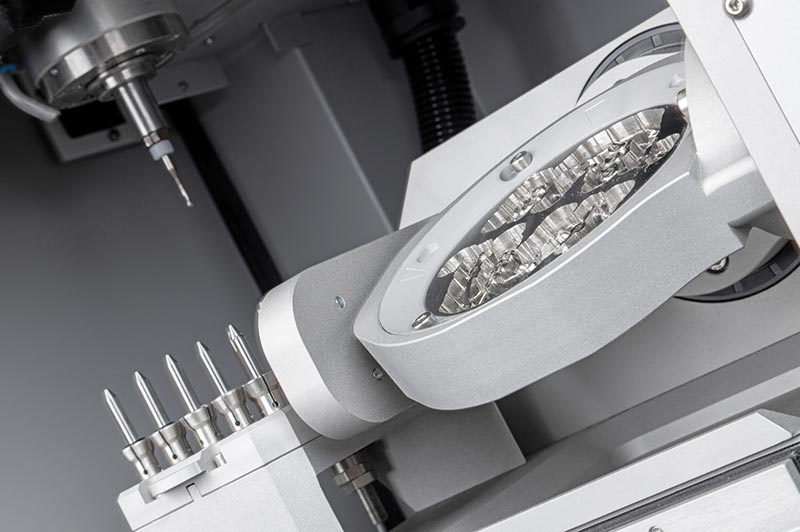

A 5-axis dental milling machine that easily processes the hardest metals - and can be accommodated practically anywhere. The Titanium D3 is our compact all-rounder. In addition to an automatic 28-position tool changer and a double-sided, ultra-stable round holder, the DEGOS Titanium D3 has many other technological refinements.

Power spindle Made in Germany.

The powerful 2.7 kW high-performance spindle is manufactured for us by the German quality manufacturer IMT. Created for metal, it effortlessly cuts all materials in the milling chamber of the DEGOS Titanium D3 - especially CoCr and titanium.

Perfect results through high-performance components

High-quality AC servo drives with 400 watts of power - four times that of the predecessor machine - and precision threaded rods from world market leader THK ensure maximum precision in the micrometer range, perfect for telescopic technology and direct screw-retained implant bridges.

Telescopic technology of the highest precision

Thanks to its monoblock chassis and 2.7 kW power spindle, the DEGOS Titanium D3 mills with exceptional smoothness and accuracy. This enables your telescopes to succeed with the highest precision and absolutely reliable reproducibility. The sophisticated temperature control and intelligent software functions guarantee a perfect fit at all times - even when working with multiple telescopes over long spans.

Exemplary flexibility and user-friendliness

With the automatic 28-fold tool changer, an optimum milling stock for all materials is guaranteed. With our sister tool technology, worn tools are automatically changed in the DEGOS Titanium D3.

One machine for all materials

You can mill all materials with the DEGOS Titanium D3. Of course, soft materials such as zirconium oxide, PMMA and wax, but also glass-ceramics such as e.max®, Suprinity®, CeltraDuo®, Enamic® and Empress®. The system is designed for heavy duty milling and also mills metal, such as CoCr and titanium, with confidence. For example, you can mill not only individual abutments from preforms*, but also bars and direct screw-retained implant bridges* from the full metal blank.

Robust high technology in a smart design.

Careful, proven industrial design combines high-quality mechanical and electronic components in the DEGOS Titanium D3. For the first time, the new Titanium D3 has an integrated industrial computer which, in addition to its superior computing power and speed, also has the best protection against dust, moisture and extreme temperatures.

Minimized maintenance, maximized precision.

Absolute Encoding enables a new type of axis control in the Titanium D3 without limit switches and sensors. This technology not only increases precision to the highest level, but is also more reliable and requires less maintenance.

Record-breaking speed for a new level of productivity.

New milling strategies and an expanded tool changer with 28 positions ensure sensational speed values: A CoCr veneer coping is produced in less than 8 minutes, a bite block splint in less than 11 minutes pure milling time!

Further information

- Technical data

- Downloads

- Bewegungen X-/Y-/Z-Achse: 200 x 100 x 90 mm

Bewegungen A-/B-Achse: bis 30° / bis 30°

Achsen: 5

Antriebe: AC Servo in allen Achsen

Antriebsleistung: 400 Watt pro Achse

Spindelhersteller: IMT (Made in Germany)

Spindelleistung: 2.700 Watt

Spindeldrehzahl: 60.000 UpM

Werkzeugwechsler: 28 Aufnahmen

Qualität Blankhalter/Werkzeugwechsler: Aluminium-Hochleistungslegierung

Kleinste Schrittgröße: 0,1 μm

Fräsgenauigkeit: < 5 μm

Wiederholpräzision: < 2 μm

Max. Vorschub X-/Y-/Z-Achse: 330 mm/s

Positionskontrolle: Absolute Encoder

Durchschnittlicher Energieverbrauch: 1,5 kW

Maximaler Energieverbrauch: 3,2 kW

Anschlussleistung: 220 Volt / 50 Hz, 3kW max. Leistung (norm. Steckdose)

Maße (BxTxH): 60 x 70 x 80 cm

Nettogewicht: 140 kg

Versandgewicht: 150 kg

Standby-Lautstärke: ca. 63 db

Betriebslautstärke: ca. 70 db